Let’s talk today about metal lowers. For sake of argument, we will be talking about metal lowers as it applies to the 80% world. For further clarity, we are going to focus on aluminum receivers. After a bit of research, I found that most of the companies that have offered the dream of other metals, namely bronze and titanium, have mostly just pushed out dreams with no product. In fact, the only titanium company I could find that still had a website was Amalgamated TI (http://www.amalgamatedti.com/). Their last update was in September of 2016, and as far as I can tell no one is carrying their lowers. They also mentioned returning to Shot Show 2017, but we certainly didn’t see them there.

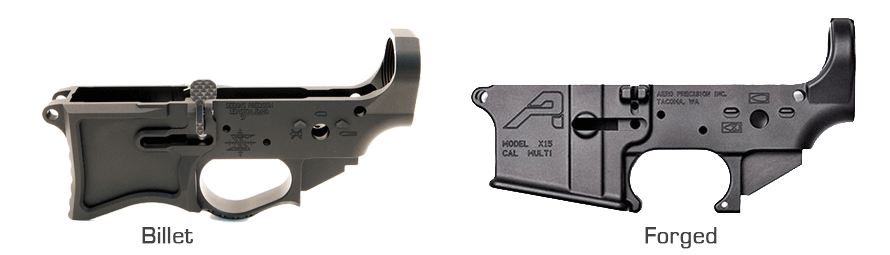

The first comparison in aluminum is cast vs forged vs billet. This focuses on the different processes involved with turning the aluminum from a chunk of metal into a lower. Here is a great article, with pictures, comparing all of the different processes and the pros and cons.

You will find all kinds of arguments for each one, but here is the real kicker: Functionally, they are all the SAME! The manufacture of the lower is more important than the process. If in the normal course of owning a rifle, you can manage to damage ant of these three types beyond function, then maybe firearms are not for you. That said, here are the three factors to keep in mind:

- What is your budget? The cast lower will be the cheapest. The billet will be the most expensive. The forged is slightly more than cast. So, what do you want to spend?

- Who do you believe? You can trust me, look in to the true statistics and compare them to what a lower receiver actually goes through, or you can believe somebody on another blog or forum somewhere.

- What do you want? Ultimately, all three options will absolutely thrill you, if it is what you want. Do you want to show off your rifle you built for under $400? (Yes, it is possible) Do you want to brag about how the metal grains are aligned in your billet aluminum lower, thus making it the strongest? At the end of the day, it is YOUR rifle, and you should have what you want.

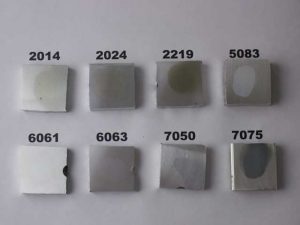

When you get past the process, there are basically two alloy types for forged and billet. You have either 6061-T6 or 7075-T6. Cast is almost always 381. So what do all of these number mean? 6061 and 7075 designate the mix of components in the aluminum. Here’s a nice long discussion, free from AR opinions, about the differences in the alloys:

http://blog.onlinemetals.com/6061-vs-7075-aluminum-alloy/

TLDR – 7075 is technically stronger and 6061 is technically cheaper

Here’s where the rubber meets the road: 6061 is used in automotive and 7075 is used in aircraft. An AR lower experiences much less stress than either of those applications, so unless you plan on driving it or flying it, either will suit you fine. Here is the catch though, on forged, 7075 is more prevalent, and therefore cheaper. Most manufacturers of billet only use one alloy, so you probably won’t have a choice. So there you have it. Don’t spend a lot of time worrying about it. Get the lower you like from the company you like.

As an addition, no matter what the internet tells you, you can’t tell the difference just by looking at it.

Source: http://www.practicalmachinist.com/vb/general-archive/6061-t6-7075-t651-aluminum-84351/

The two sure ways to tell are to use a center punch hardness test or discolor it with Sodium Hydroxide (Lye). Both of these will damage your receiver, so I suggest buying from a reputable dealer.

Thanks for reading my ridiculously long post that basically says there is no difference, get what you want.